Case Study: The Winstone Aggregates Problem

Submitted: 10 Mar 2008

Operations Research Topics: LinearProgramming, BlendingModels

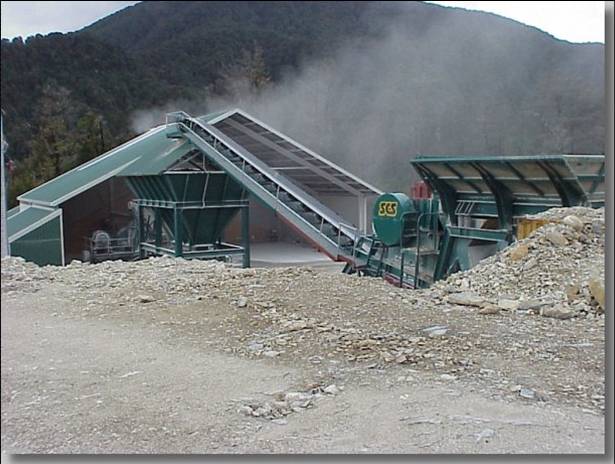

Application Areas: Aggregate Manufacturing

Contents

Problem Description

Winstone Aggregates NZ- Coarse

- Fines

- LowBase

- HighBase

- Sand

- Scalpings

- Scoria

- Sealchips

The amount of each raw material available is limited as the Resource Consent Act

The amount of each raw material available is limited as the Resource Consent Act Winstone Aggregates wants to maximise the profit it receives to determine the best use of its raw materials, but it has to consider factors such as

Winstone Aggregates wants to maximise the profit it receives to determine the best use of its raw materials, but it has to consider factors such as - the demand for different aggregates varies during the year;

- stockpiling product costs money, i.e., the holding cost;

- each aggregate is made according to a recipe that defines how it is produced from the raw materials;

- transportation costs from quarries to customer must be incorporated.

| Recipe (per tonne) | Scoria (tonnes) | Greywacke (tonnes) | Sale Price ($/tonne) |

| Fines | 0.6 | 0.9 | 70 |

| HighBase | 0.5 | 0.7 | 60 |

| Coarse | 1.2 | 0.3 | 40 |

Student Tasks

1. Write AMPL files

Return to top winstones.mod, winstones.dat and winstones.run to find a production plan. Write a management summary of your production plan.

What to hand in Your AMPL files winstones.mod, winstones.dat and winstones.run. Your management summary.

Topic revision: r3 - 2008-04-02 - MichaelOSullivan

Ideas, requests, problems regarding TWiki? Send feedback