Case Study: The American Steel Transshipment Problem

Submitted: 15 Feb 2008

Operations Research Topics:

Application Areas: Logistics

Contents

Problem Description

THE AMERICAN STEEL PROBLEM

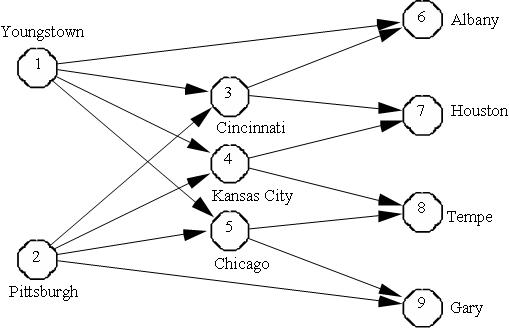

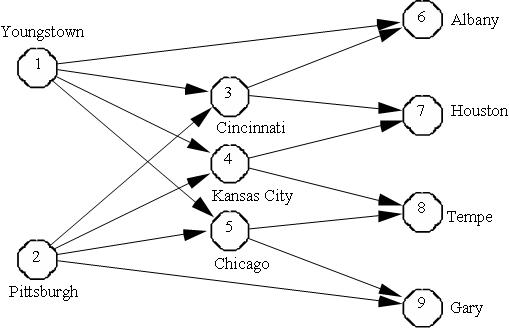

American Steel, an Ohio-based steel manufacturing company, produces steel at its two steel mills located at Youngstown and Pittsburgh. The company distributes finished steel to its retail customers through the distribution network of regional and field warehouses shown below:

The network represents shipment of finished steel from American Steel’s two steel mills located at Youngstown (node 1) and Pittsburgh (node 2) to their field warehouses at Albany, Houston, Tempe, and Gary (nodes 6, 7, 8 and 9) through three regional warehouses located at Cincinnati, Kansas City, and Chicago (nodes 3, 4 and 5). Also, some field warehouses can be directly supplied from the steel mills.

The table below presents the minimum and maximum flow amounts of steel that may be shipped between different cities along with the

cost per 1000 ton/month of shipping the steel. For example, the shipment from Youngstown to Kansas City is contracted out to a railroad company with a minimal shipping clause of 1000 tons/month. However, the railroad cannot ship more then 5000 tons/month due the shortage of rail cars.

| From node |

To node |

Cost |

Minimum |

Maximum |

| Youngstown |

Albany |

500 |

- |

1000 |

| Youngstown |

Cincinnati |

350 |

- |

3000 |

| Youngstown |

Kansas City |

450 |

1000 |

5000 |

| Youngstown |

Chicago |

375 |

- |

5000 |

| Pittsburgh |

Cincinnati |

350 |

- |

2000 |

| Pittsburgh |

Kansas City |

450 |

2000 |

3000 |

| Pittsburgh |

Chicago |

400 |

- |

4000 |

| Pittsburgh |

Gary |

450 |

- |

2000 |

| Cincinnati |

Albany |

350 |

1000 |

5000 |

| Cincinnati |

Houston |

550 |

- |

6000 |

| Kansas City |

Houston |

375 |

- |

4000 |

| Kansas City |

Tempe |

650 |

- |

4000 |

| Chicago |

Tempe |

600 |

- |

2000 |

| Chicago |

Gary |

120 |

- |

4000 |

The current monthly demand at American Steel’s four field warehouses is as follows:

| Field Warehouses |

Monthly Demand |

| Albany, N.Y. |

3000 |

| Houston |

7000 |

| Tempe |

4000 |

| Gary |

6000 |

The Youngstown and Pittsburgh mills can produce up to 10,000 tons and 15,000 tons of steel per month, respectively. The management wants to know the least cost monthly shipment plan.

Return to top

Problem Formulation

1. IDENTIFY THE DECISION VARIABLES

The decision variables for this problem are the same as for the transportation problem, the

Flow of goods (cases of beer in The Beer Distribution Problem, tons of steels here) through the network. In <span style=

Return to top

Computational Model

The computational model...

Return to top

Results

Implementing the usual script file with

transshipment.mod and

steel.dat (with the

Cost modification) gives us the optimal

Flow variables:

<img width=

Return to top

Conclusions

There is quite a bit of information to summarise and many ways to present it. Some suggestions include:

- Summarise the problem as usual and list the shipments that American Steel should make (similar to the transportation problem);

- Summarise the problem as usual and present a table of shipments that American Steel should make;

- Draw the network formulation for the problem (being sure to specify what the labels mean). Then draw the actual solution on top of the network formulation. You could colour code flows long arcs to show if they are at their bounds.

Implementation and Ongoing Monitoring

Given that the solution is very sensitive to the supply and demand amounts, careful consideration of the accuracy of these figures is important. Making sure that the bounds on the arcs are reliable is another concern.

Ongoing monitoring of the supply, demand and bounds will help American Steel to keep making good decisions. As shown in the parametric analysis, ongoing negotiation of transportation prices along important routes will help American Steel reduce their expenditure.

Return to top

Extra for Experts

Another common network flow problem that uses almost the same model as transshipment is the

maximum flow problem. The objective of this problem is to maximise flow through the network. The only changes to

transshipment.mod are:

- A new variable

FlowOut is introduced at each node;

-

FlowOut has lower and upper bounds, often the upper bound is set to as the Demand at the nodes;

-

FlowOut replaces Demand in the ConserveFlow constraints;

- The

ConserveFlow constraint becomes an equality constraint as all flow must be accounted for (no storage at the nodes);

-

Cost of transshipment is ignored;

- The objective is to maximise the total flow out of the network

sum {n in NODES} FlowOut[n];

- The problem no longer needs to be balanced.

Maxflow.mod

<span style=

Return to top

Student Tasks

- Solve The American Steel Problem. Write a management summary of your solution.

What to hand in Hand in your management summary.

EXTRA FOR EXPERTS' TASKS

- American Steel are planning a marketing campaign to increase demand in their four markets Albany, Tempe, Houston and Gary. However, they would like to know the maximum demand their distribution network can handle (in each market) before they proceed. Write a script file that uses

maxflow.mod and steel.dat to find the maximum demand they can supply in each market.

What to hand in Hand in your script file and a management summary of your solution.

Return to top

The network represents shipment of finished steel from American Steel’s two steel mills located at Youngstown (node 1) and Pittsburgh (node 2) to their field warehouses at Albany, Houston, Tempe, and Gary (nodes 6, 7, 8 and 9) through three regional warehouses located at Cincinnati, Kansas City, and Chicago (nodes 3, 4 and 5). Also, some field warehouses can be directly supplied from the steel mills.

The table below presents the minimum and maximum flow amounts of steel that may be shipped between different cities along with the cost per 1000 ton/month of shipping the steel. For example, the shipment from Youngstown to Kansas City is contracted out to a railroad company with a minimal shipping clause of 1000 tons/month. However, the railroad cannot ship more then 5000 tons/month due the shortage of rail cars.

The network represents shipment of finished steel from American Steel’s two steel mills located at Youngstown (node 1) and Pittsburgh (node 2) to their field warehouses at Albany, Houston, Tempe, and Gary (nodes 6, 7, 8 and 9) through three regional warehouses located at Cincinnati, Kansas City, and Chicago (nodes 3, 4 and 5). Also, some field warehouses can be directly supplied from the steel mills.

The table below presents the minimum and maximum flow amounts of steel that may be shipped between different cities along with the cost per 1000 ton/month of shipping the steel. For example, the shipment from Youngstown to Kansas City is contracted out to a railroad company with a minimal shipping clause of 1000 tons/month. However, the railroad cannot ship more then 5000 tons/month due the shortage of rail cars.